LOADRITE™ offers a range of on board weighing systems designed for wheel loaders, from entry-level through advanced functionality options. Whether you require basic weighing information for a compact loader, or greater accuracy and data capture capabilities for production-sized loaders, we have the solution for you.

The LOADRITE™ wheel loader scale product line is widely recognized as setting the standard for our industry. This is the result of over thirty years industry expertise gained by working closely with machine owners and operators.

The accuracy you can expect from a LOADRITE™ on board weighing systems is demonstrated by the L-SERIES™ Product Overview Brochure

L2180

Is your output optimized for maximum profits? Do you want to maximize machine utilization and minimize fuel usage? Can you benefit from improved efficiency?

The Trimble LOADRITE™ L2180 is designed to produce an accurate and consistent weight every time. Consistent weighing performance is just as important as accuracy to efficient loading operation.

Using proprietary FACT™ (Friction and Ambient Compensation Technology) software, the L-2180 calculates an accurate weight, regardless of time of day, machine type, operator or temperature. Along with simplified usability and the same rugged reliability that Trimble LOADRITE™ stands for, the L2180 delivers a new dimension of consistent weighing performance.

DATA SHEET ▸

HOW IT WORKS ▸

OPERATOR TRAINING ▸

Printers

A standard report includes:

Date and time

Company name

Loader/operator identification

Onsite loading location

Required amount of product

Truck identification

Docket identification

Product loaded and total truck payload weight

Individual bucket load weights

LP950 AND LP930 PRINTERS ▸

What can the L2180 Bring to Your Business?

Improve profits

Eliminate double handling of material by loading right first time

Avoid overload fines by ensuring trucks are loaded to the correct value

Reduce haulage costs by avoiding unnecessary trips caused by under loading

Process improvement

Track individual machine efficiency

Know inventory and stock levels

Monitor machine stress to schedule preventative maintenance

Increase productivity

Prevent truck turnarounds at the weighbridge, reducing cycle times

Sell more product without adding equipment or personnel

Achieve consistent loading from machine operators, regardless of experience

Sustainability

Minimize fuel usage of loaders and trucks and maximize tons per litre/gallon

Maximize the utilization of the machinery already on site by identifying unused capacity

Improve overall equipment effectiveness

Versatility

No matter what material you’re loading, moving or managing, Trimble LOADRITE™ has expertise in applying our proprietary technology to a variety of wheel loader applications:

Aggregates

Scrap handling

Waste/recycling

Construction

Municipalities/Councils

Landscaping

Mining

Logging

How It Works

1. Pressure Transducers

2. Triggers

3. Indicator

4. Slope Compensation Kit

5. Printer

6. Data Communication

L2150

The L2150 is a high precision onboard loader scale, it offers accuracy and reliability with basic data functions.

By using multiple-point triggering, speed compensation and dual pressure measurement the L2150 offers high level weighing accuracy regardless of lift speed and loader movement. All you need to know is that trucks will be loaded to the right weight first time.

Data entry and logging features of the L2150 allow you to begin monitoring the efficiency and productivity of any front end loader operation, these features are not as extensive as those of the L2180.

DATA SHEET ▸

FORCE

Now every machine operator can quickly and easily load trucks exactly to their target weight. The LOADRITE™ Force™ helps gauge accurate loading through its no-frills interface.

Industry leading weighing accuracy ensures trucks are correctly loaded before they get to the weighbridge. Wheel loader scales cut down on congestion and reduces waiting time increasing your customer’s satisfaction.

Built on reliable field proven hardware, the LOADRITE™ Force™ is a user-friendly, high performance wheel loader weighing system. It has fewer functions than some of the other Loadrite models, making it a fast and easy system to use.

Just like the high-end L-2180™ and L-2150™ models, the LOADRITE™ Force™ is multiple-point weighing enabled. This feature allows weighing to be carried out in transit, without slowing down the operator.

The system is ideally suited to applications that require accuracy of loading, but for which more advanced features are not necessary.

DATA SHEET ▸

LR360

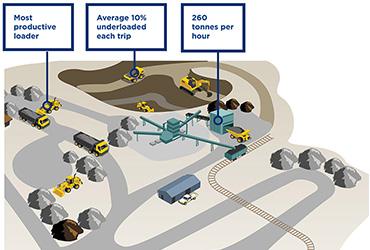

LOADRITE™ 360 is a connected quarry solution that can holistically improve loadout operation through performance metric tracking, job data automation, and real-time 360º job visibility.

LR360 connects the loader and scale house to provide data sharing of loadout jobs which result in greater efficiency, improved visibility and higher product sales.

BROCHURE ▸

DATA SHEET ▸

InsightHQ Connection

LR360 performance reports tracks loader metrics including tonnes per hour (TPH) across multiple or individual loaders, actual time spent on truck loading activities and loader operator efficiency to highlight staff training needs

POS System and In-cab Automated Connection

Two-way automated communication shows jobs requested at the scale house as a job list inside the cab, and completed loadout data is fed directly into the scale house POS. This reduces double entry work and data entry errors for both the operator and scale house attendant. Accurate on-screen job data reduces error-prone verbal comms chatter, and allows more time for loading.

Real-time Job List

The LR360 in-cab indicator clearly presents a list of loadout jobs in order of priority and the truck ID. By providing simple, relevant and organised job data to the operator they are empowered to deliver faster with a sense of urgency and priority across the site. The list also provides richer load out job queue data, reduces verbal communication, and errors, which reduces truck waiting time and happier customers.

True Tare Trucking Loading

The truck and payload is measured three times for each loadout: upon arrival at the truck scale (weigh bridge), at loadout on the loader scale and true payload is verified on departure. True truck payload measurement maximizes tonnage and optimizes truck utilization for the customer and maximizes product sales at the scale house.

How It Works

LR360 decreases rework and miscommunication by wirelessly synchronizing data between the loader and the scaleshouse.

As the empty truck arrives its weight is recorded and material request data entered into the POS.

The job details are wirelessly transmitted to the loader and displayed in the cab in a prioritized list.

When the job reaches the top of the list, the loader operator can go to the material, identify the truck from the ID and load precisely to the target weight.

At the completion of the job, the data is returned to the scale house and billing is automatically adjusted before the truck arrives to tare out.

The quarry manager is able to see loadout operations in real-time with a clear view of workload, productivity and performance.

L3180

LOADRITE™ L3180 SmartScale for Wheel Loaders.

When the pressure is on and customers are waiting, you need to perform faster without compromising accuracy and precision. The new L3180 SmartScale for loaders adjusts for rough terrain, technique, and movement so new and skilled operators can load with greater accuracy, precision and speed.

BROCHURE ▸

DATA SHEET ▸

What is a SmartScale?

A SmartScale is the next generation of onboard weighing that uses artificial intelligence for more accurate, precise and faster loading. It also connects machines and devices for the collection and syncing of loading data.

The L3180 SmartScale offers:

Weighing artificial intelligence

Connected Quarry connectivity including built-in WiFi and GPS

Multi-axis Inertial Measurement Unit (IMU)

Best-in-class interactivity and interface